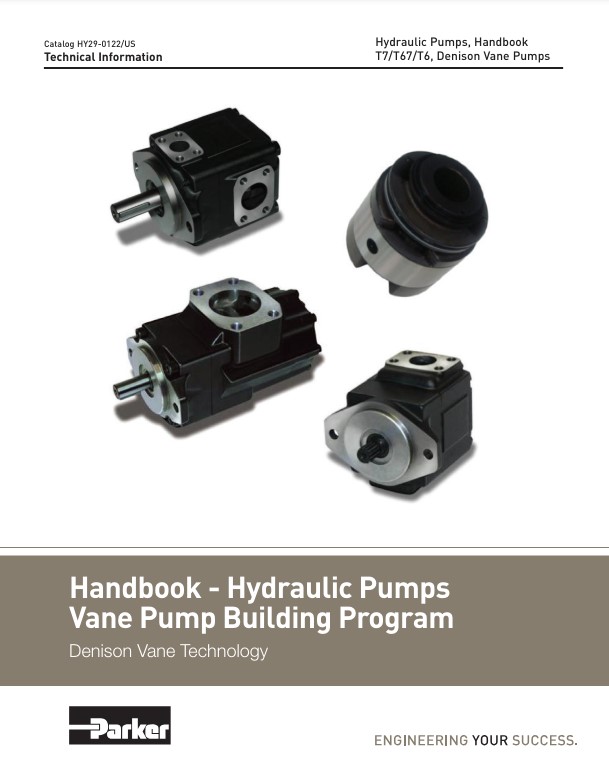

Parker Vane Technology

Product Information

1.1 General Product Information

Parker vane pumps and motors are hydraulic components used in various industrial applications. They are known for their high efficiency, reliability, and long service life. Denison vane pumps feature a unique vane design that ensures consistent performance and smooth operation.

Denison pioneered the double lip, with a leading edge to keep contaminants out. Should last about 5 times longer than other vane units.

Product Information

1.3 FAQ

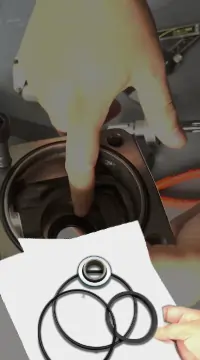

Q : What is the difference between seals?

Buna nitrile seals are standard seals. EPR seals are used for phosphate hydraulic fluids and glycol-based fluids. Viton seals are designed for high pressure and high heat applications.

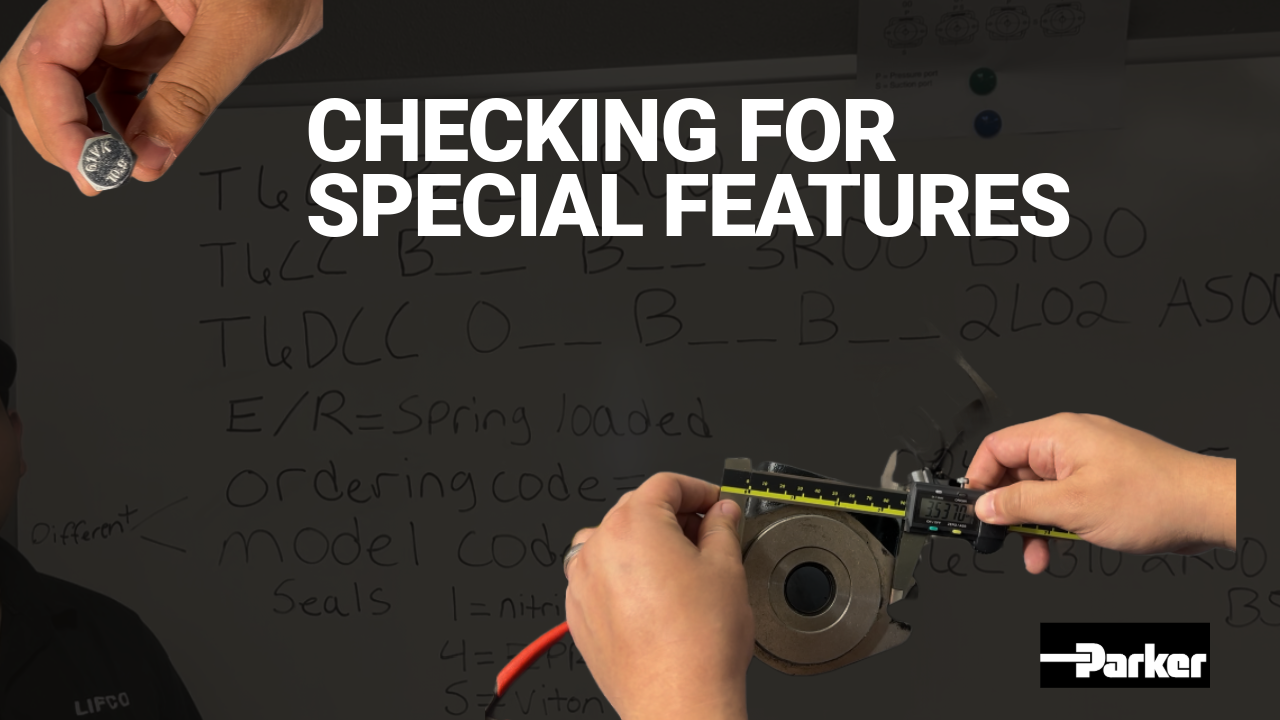

Q : What do the E and the R represent in the model code ?

The E and the R represent spring loaded vanes. They are useful for low pressure applications, where there is not a lot of force pushing the vanes in the rotor toward the cam.

Q : What is the difference between the model code and the ordering code?

In a perfect world: nothing. The ordering is meant to be all you need to place an order, but people can change the model code after it shipped from the factory without giving it a new ordering code (ex. Changing the control). So best to provide both. We will advise if there is a discrepancy. See our vane model code video here.

Q : What is the difference between mobile and industrial?

We used to make the distinction between the two but it is no longer as common.The major difference is that the mobile units - labeled M - allow for speeds down to 400 RPM at full pressure, whereas industrial units go down to 600 RPM. Both units can reach speeds up to 2800 RPM.

Q : What is the B in the cartridge before the cam size?

B stands for Bi-Rotational.

Q : What is Bi-Rotational?

It means it is possible to change the rotation, but you would have to take the unit apart. Instructions can be found here.

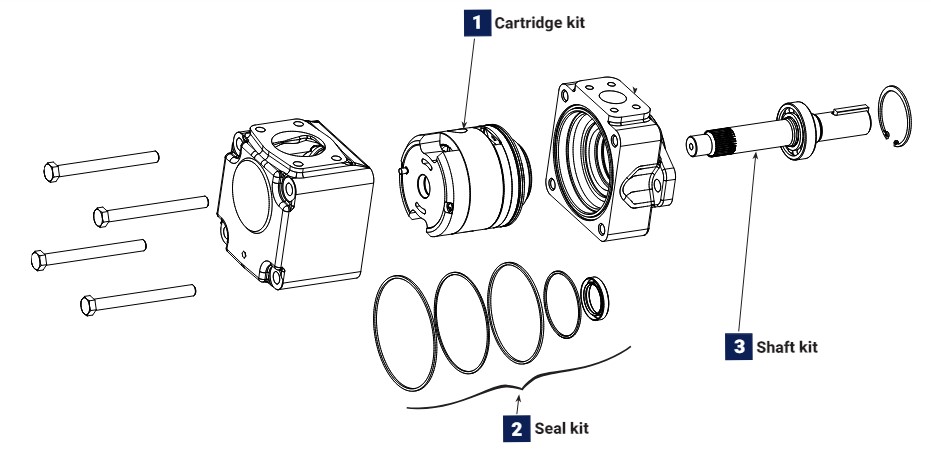

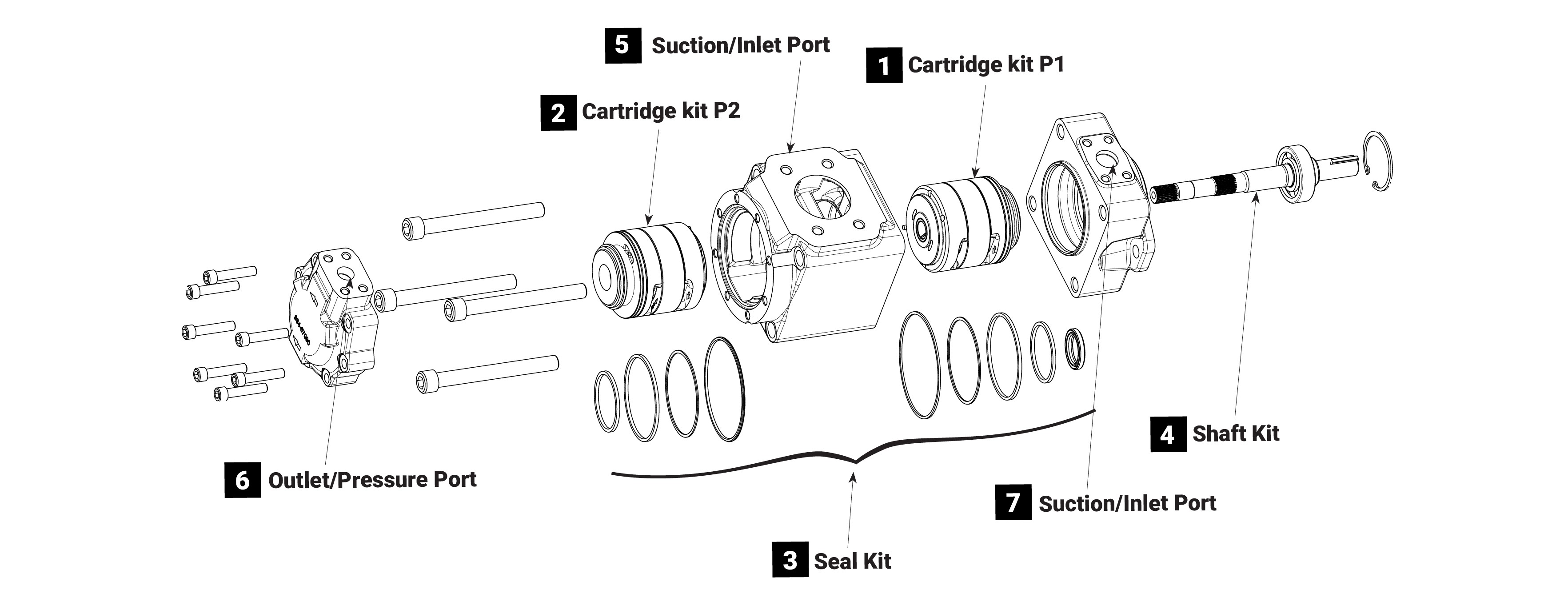

Q : How to service the units, “ change cartridges, apply seal kit etc

You can track your order by logging into your account on our website or by using the tracking number provided in your confirmation email.

Q : What is the difference between the T series and the M series?

The T series are vane pumps and the M series are vane motors.

Have a different question and can’t find the answer you’re looking for? Reach out to our support team by sending us an email

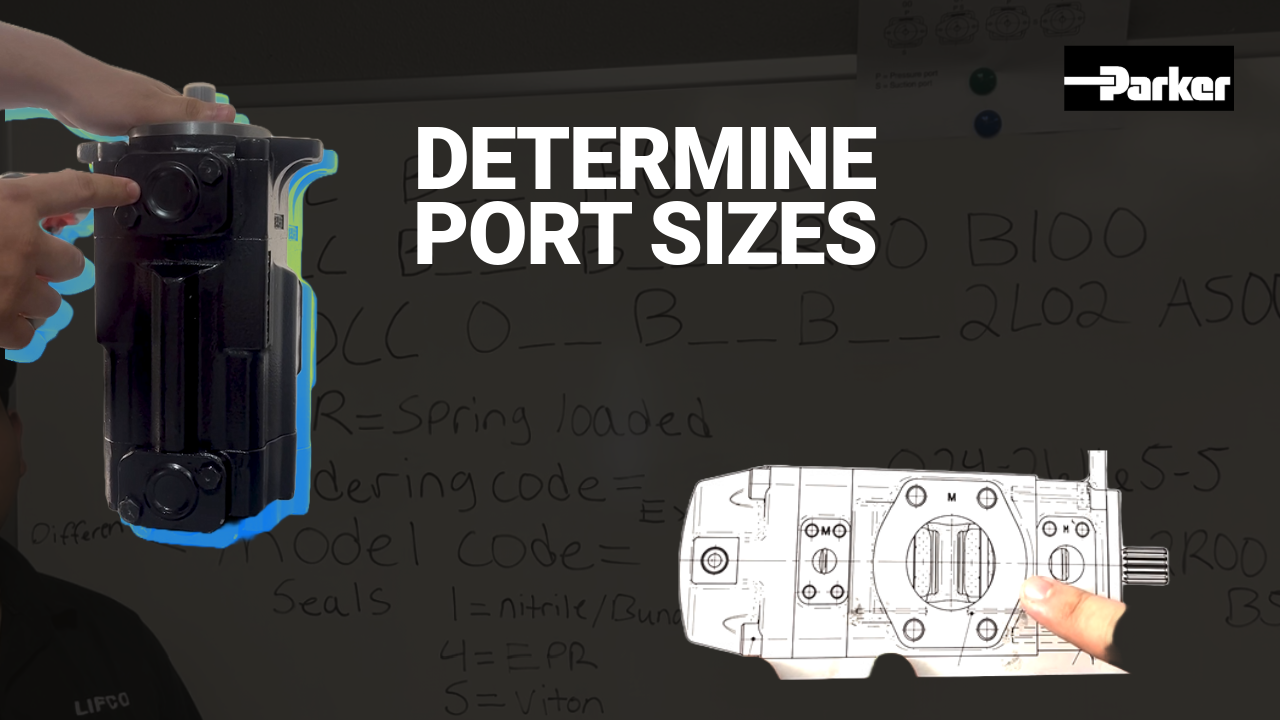

Pump Identification Guide

We used to make the distinction between the two but it is no longer as common. The major difference is that the mobile units - labeled M - allow for speeds down to 400 RPM at full pressure, whereas industrial units go down to 600 RPM. Both units can reach speeds up to 2800 RPM.